Table of Contents

By James Pidacks Dec. 13, 2023

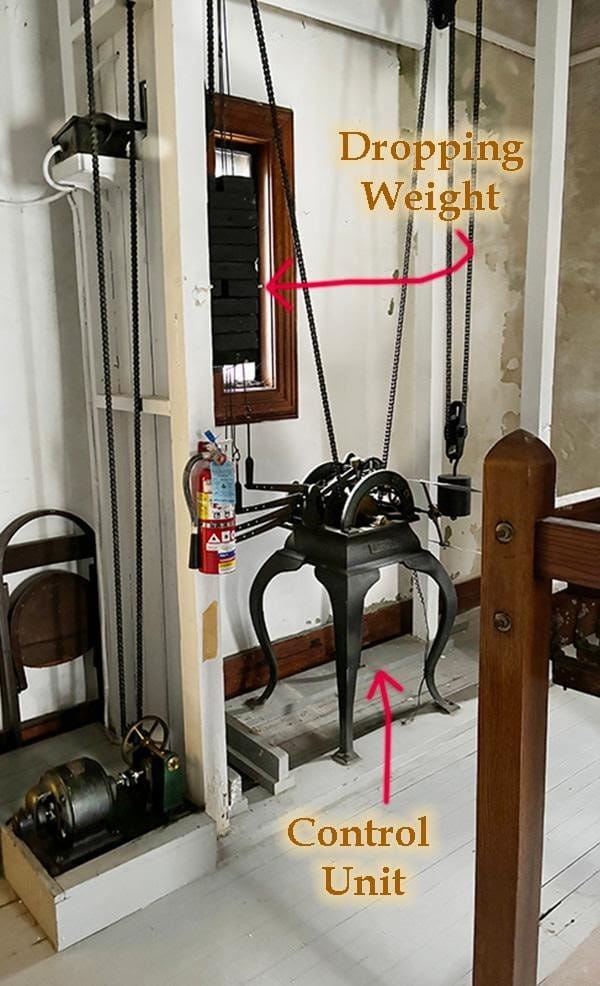

How do the bell chimes work to sound on the hour? This learning journey started while working with a vendor on security cameras. I was in the bell tower for the first time. I looked at all the equipment and wanted to learn more.

When you’re in the lower level hallway near the restrooms, do you ever wonder why we keep a dead clock by the stairs? Well, it’s more than that. It’s the original clock that controlled the chimes.

There is a paper tape loop with holes (see photo) and a reader inside the case, running along the left. When the old clock worked, its movement would move the paper tape. When a hole was reached, a switch closed, and the unit up in the bell tower got to work and rang the chimes. Whenever the weights reached the floor, the motor turned on and lifted the weights back up to be ready to ring the chimes again. The paper tape system died years ago. Who knows if the clock would still work if we wound it?

Now, the church has a digital control box on the wall around the corner from the clock. It replaced the mechanical clock. If I were taller, I’d be able to read the instructions. So now we know how we kept time for the chimes in the old days and how we do it now. The next question was how to repair the motor coupling and who to call.

I returned to the bell tower and found this set of handles which is used to play the chimes and has the vendor name MeNeely & Company, Watervliet, NY (near Rochester). The company opened in 1826 and closed in 1952 (before I was born).

Amazingly, all of the bells, chimes, and controller was installed in the 1920s and still work today (except for that clock paper tape gizmo). The damaged coupling was replaced with a metal and plastic spider coupling, which cost about $20. It took under an hour to replace. We included these images of the bells and control armature to round out a glimpse at the uppermost level of the bell tower.

James Pidacks is a member of the Unitarian Building and Grounds Committee.